Corn sticks are one of the favorite children's treats, which adults sometimes do not refuse. And in recent years, salty options have appeared, as well as versions of corn sticks with various flavors - with cheese, bacon, and so on. How are they made from a factory, and can they be made at home?

The manufacture of such a product does not pose any particular difficulties. The sticks are made from simple, inexpensive raw materials, the plant is capable of producing tons of such a product daily. Making sticks at home is also possible.

What are corn sticks made of?

In order to produce this product, the plant orders large quantities of raw materials. The low price of finished products is associated with the low cost of the original ingredients. First of all, corn flour is required, created necessarily from hard varieties of golden cereal. You also need deodorized vegetable oil, salt. Powdered sugar is used to give a sweet taste, it is present in classic recipes. Salty sticks do without sugar, but flavoring additives, sometimes dyes, may be required to make them.

Interesting fact: corn is really cereal, like wheat, rice, maize. This is not a vegetable. It is very different from the usual cereal in structure, the difference in morphology is due to the fact that its evolution and growth occurred on another continent.The closest cultural cousin of corn is maize.

What equipment can produce corn sticks?

Modern plants are equipped with special lines consisting of several pieces of equipment connected by conveyor belts. This approach allows you to produce the product without interruption. At the beginning of any line is a mixer in which the cereal is loaded - here it undergoes preliminary training. Also in many lines there is a built-in mill, which allows you to get powdered sugar from sugar.

Extruder, panning equipment, powder dispenser, and filling device continue the line. The power of the lines can vary, it can be either small or increased, depending on this indicator, the unit allows you to create from 30 to 250 kg of product per hour. It takes about 10 minutes to make each individual batch. Modern models do not require the constant presence of an operator; they are fully automated.

Corn stick production process

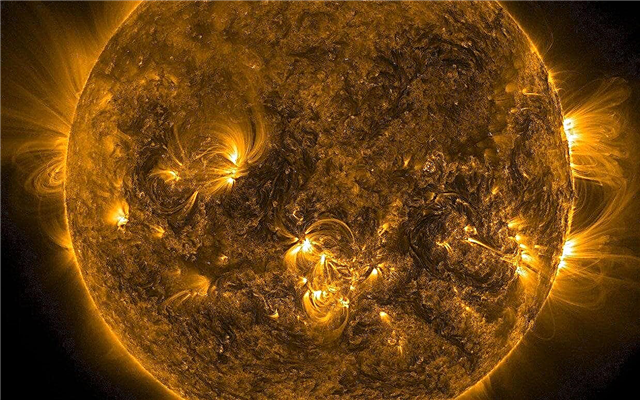

The first step in the production of goodies is to feed the cereal into the extruder. Here it is heated to a temperature of 40 - 150 degrees, subjected to high pressure. The raw material acquires a porridge-like consistency, and is fed to the matrix with holes, upon exiting through which the corn mass swells sharply, becomes airy. This is ensured by a change in pressure. On the matrix, the sticks take the necessary shape - they can be not only oblong, as in the classic version, but also round, square, any other shape.

The sticks emerging through the holes of the matrix are not yet the final product; they are moist and tasteless. They must be dried.The process is carried out in a drum, where the sticks get further. Then, almost finished products get into the coating complex, where flavoring additives in the form of powder are applied to them - if we are not talking about sweet glazed varieties of delicacies.

In addition to additives, vegetable oil can get into the device in the form of a long drum, which is preheated and spreads evenly on the sticks. Oiling is important for sticks that are sweet and glazed. After oil treatment, they fall into the next drum, where they are sprinkled with powdered sugar. It melts under the influence of oil and creates a glaze.

After this processing step, the product can be considered ready to eat. The sticks arrive at the packaging, which is also performed automatically. The packaged product is transported to the warehouse, and then sent to the base, to the stores. Once on the shelves in the retail sector, it becomes available to all customers and quickly sold. The demand for corn sticks is high, they have a pleasant taste, affordable price. Sticks are useful because corn has a lot of nutrients and trace elements.

Can I make corn sticks at home?

Cooking corn sticks at home is possible, but only with a special apparatus. Home units are capable of producing up to 15 kg of sticks per hour, working not only with corn, but also with other cereals. But in most cases, people emphasize that this delicacy will be more profitable to buy in a store, because it costs not at all expensive.It makes sense to use home-made solutions only within the framework of culinary creativity - if you really like to cook on your own.

Thus, the production of corn sticks is not a complex process, however, requiring special equipment. In factories, products are produced in large batches, using inexpensive raw materials and modern lines that allow you to work continuously, delivering one batch of products after another.